An iconic silhouette that has become part of the city’s, region’s, and even a university’s emblem; a structure that locals inherently perceive as part of their identity; a national cultural heritage and a building nominated for entry on the UNESCO World Heritage List. All of this describes a single building that has crowned the summit of Ještěd Mountain above the northern Czech city of Liberec since 1973 – the Ještěd Hotel and Television Transmitter.

Anyone who has traveled through the Czech countryside knows them – tall dark blue cylinders rising high, displaying the iconic logo of the Vítkovice Ironworks, clearly announcing a place associated with agriculture. These are the enameled tower silos and tanks known as "Vítkovice" — symbols of agricultural industry of our countryside.

The path to their production was laid out during a symposium of agricultural experts in May 1966. At the time, the state was trying to provide domestically produced staple foods, which necessarily required the industrialisation and intensification of agriculture. The symposium therefore addressed how to increase the volumes of stored feed with a high nutrient content and chose silage towers for storing silage, grain preservation and corn cobs as the most suitable option based on local conditions, which had already proven effective in imported models.

A Revolution in Farming from the Heart of Heavy Industry

The towers were a significant development for agriculture. The forage was cut, left to wilt and piped to the towers where it was lacto-fermented. Silaging allowed to store feed with more nutrients, thus increasing production of milk and meat, reducing the amount of forage needed to be grown due to better forage use, increasing the area available for grains. Moreover, mechanization reduced the amount of human labor required by almost half compared to traditional harvesting.

The production program was approved in November 1965. The first test tank was manufactured by by Vítkovice Ironworks Plant 6 in February 1966 and delivered to the state farm in Bajč near Komárno (today in Slovakia). In May of the following year, the trademark "Moravia" for silage towers was registered, followed later by "Moravit." However, this was not the first time that Vítkovice had undertaken such a project. By 1936, the company had delivered steel silos with a capacity of 1,000 tons to the former Carpathian Ruthenia. But now production was coming in much larger volumes.

From Prototypes to Mass Production

The construction of silage towers was standardised, reaching a 12-metre height and a 6-metre diameter. They were made of steel with the characteristic shell made of enamelled sheets of cobalt blue colour, which overlapped each other and were connected by screws. The enamel protected the tank from weather, chemicals and abrasion, giving it a long service life. Absolute gas-tightness was provided by a special sealant. The tanks were equipped with machinery such as picking milling cutters, sweepers, and forage cutters supplied by Zbrojovka Brno, and since fermentation produced a lot of carbon dioxide, the tank was also equipped with two plastic bags to balance the pressure.

The price of one tower was set at CSK 137,000, and together with installation it cost the farms CSK 223,700. The return on investment was calculated to be less than five years.

The production was initially unit-based, but since it was assumed that Czechoslovak agriculture would need a total of 40-50,000 units and the required production would be 2,500 units per year, the Ministry of Heavy Industry issued an investment assignment for the construction of a production line worth CSK 73 million. The plant was put into operation in August 1968.

New Challenges, New Products

Initial sales were strong, the ironworks immediately receiving 6,000 orders. By the end of the following year had delivered 720 silos for the Czechoslovak and international markets. However, in the following year, changes in national economic policies led to reduced state support for agricultural enterprises, which lost interest in investing in silage towers.

Since the production line operated at only one-third of its capacity and was manufacturing for stock, the idea emerged to diversify the tanks' use. They were adapted for storing other materials such as grain, granulate, fertilizer, wastewater etc. The design was based on a standardized model and thus the towers differed from each other only by other components or machinery – for example, silage and haylage silos could be identified by their concrete base and conical roof, the grain storage towers by the conical hopper, and wastewater tanks by the absence of a roof.

An Enduring Symbol of Innovation and Progress

The planned service life of Vítkovice silos and tanks was 40–50 years, though some can still be found in the landscape today. Their production is continued by one of the successor companies of Vítkovice Ironworks, and thus the continuity of this iconic product can be observed not only in Czech Republic, but on all continents.

The article was written within the project: https://sincere-project.eu/

Read also:

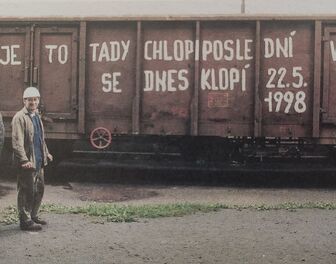

The Last Blast - the End of One Era, and a New Beginning

It was Sunday morning at 8.30 a.m. and a glowing stream of pig iron began to roll under the blast furnace No. 1 at the Vítkovice Ironworks, accompanied by a sizzle of hot sparks as it had so many times before. A blast was taking place under the furnace. This time, however, it was different, it was watched by 1,200 employees, it was 27 September 1998 and this blast was the last ever in Vítkovice.

I am a witness of modern Czechoslovak history

The Federal Assembly – that is my name. Welcome to Prague. Who am I? I have stood through all the crucial decisions our republic has faced since 1948, for once I served as the home of the National Assembly. From 1995, I became the headquarters of Radio Free Europe – and since 2009, as part of the National Museum, I have been safeguarding the treasures of our history.

When Our Fire Went Out – What Would Become of Us?

We are Blast Furnaces No. 4 and 6. For decades, we stood here with our flames burning day and night. But in September 1998, our fire finally went out. And with it came a big question: what would happen to us and to the entire Vítkovice complex?